- EXPERIENCE & CREATIVITY

Design

Hortus designs for certification and production while mastering the use case of the considered IoT project.

Hortus Technologies leverages its experience and methodologies to bring your IoT project to life.

Hortus Technologies specializes in the field of connected devices.

An engineering hub, strategic consulting, and a measurement laboratory.

Our methodologies and industrial experience enable us to anticipate and master the challenges of electronic and radiofrequency product development, from concept to industrialization.

Hortus designs for certification and production while mastering the use case of the considered IoT project.

Hortus Technologies leverages its experience and methodologies to bring your IoT project to life.

Here is a spectrum of our skills, acquired over numerous years, particularly in the development and industrialization of products in the Smart Metering and Smart City markets.

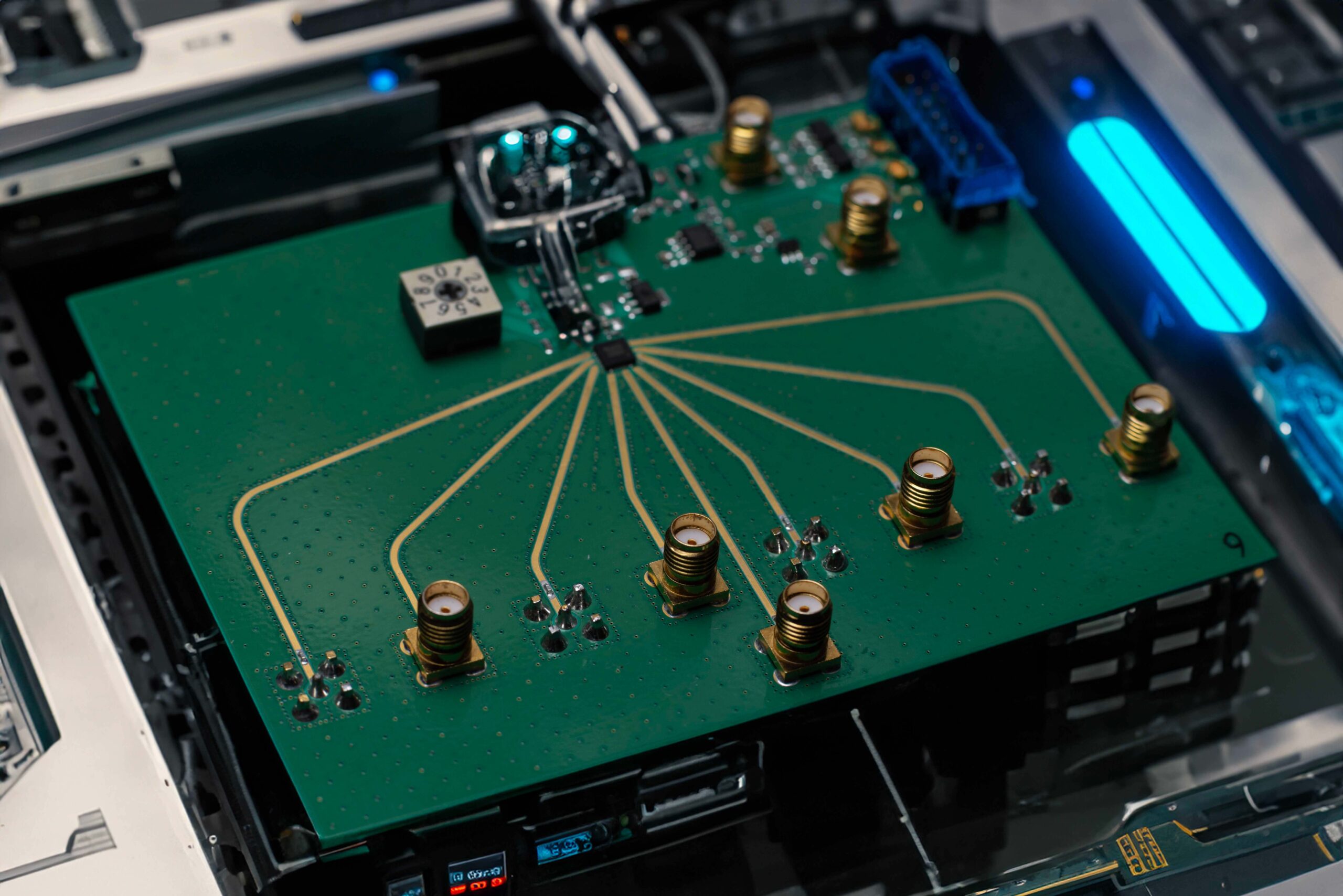

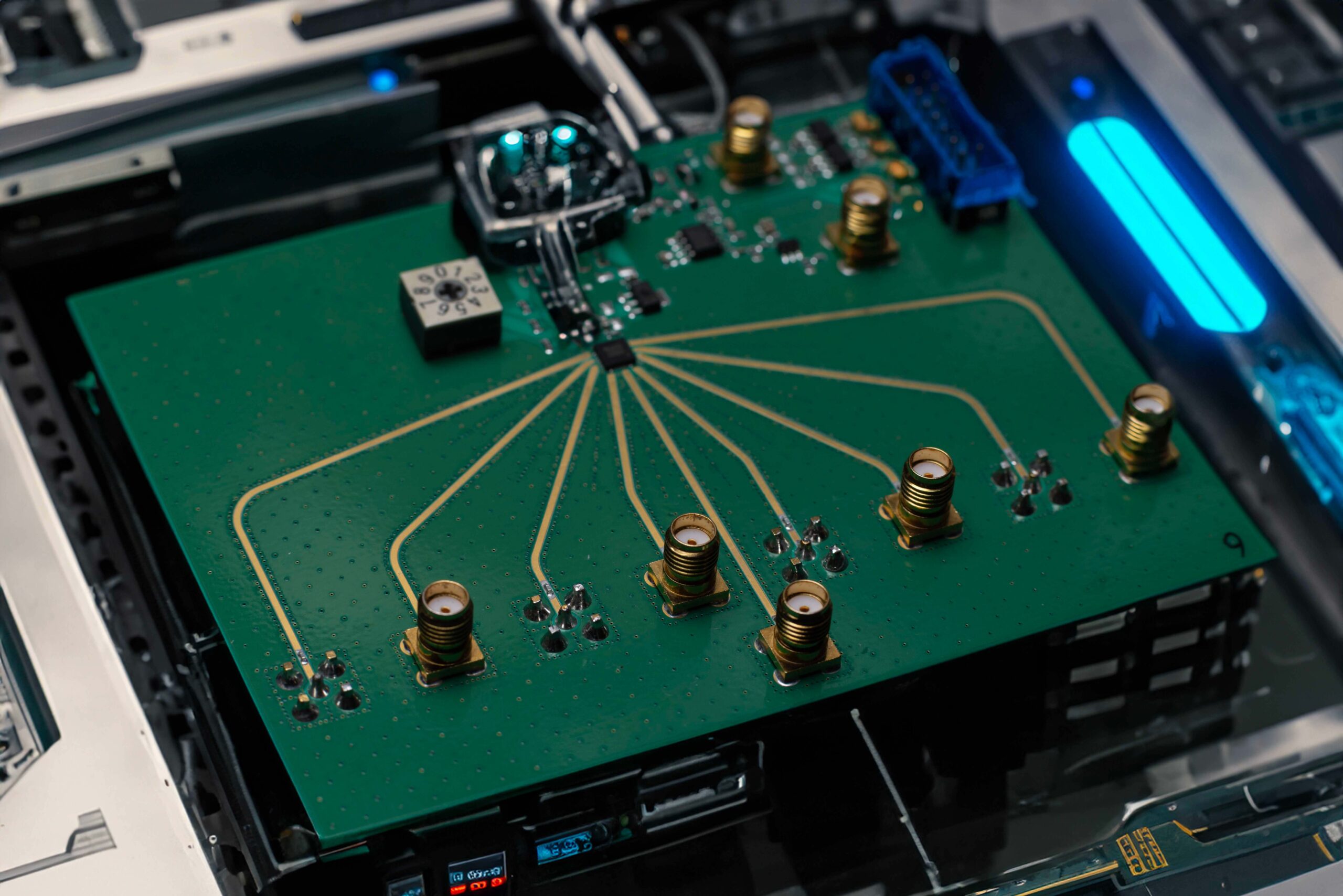

We are experts in the design of front-end components, including elements such as switches, low-noise amplifiers (LNA), power amplifiers (PA), phase-locked loops (PLL), filters, etc. Our expertise extends to the design of integrated circuits and the integration of transceivers and radio modules.

We have solid experience in NFC and RFID technologies at 13.56 MHz, allowing you to integrate these functionalities into your products.

We are experienced in working on products powered by primary batteries, operating within temperature ranges of -40°C to +85°C, and providing IP68 protection rating.

Our solutions are designed for lifespans exceeding 15 years.

We master battery and power management, as well as sensor integration, offering comprehensive solutions for your analog electronics needs.

We develop Embedded software, whether for prototypes, POC’s.

We support you throughout the process, from writing specifications to schematic design, routing monitoring, and debugging.

We are capable of producing mock-ups and prototypes, setting up proofs of concept, conducting tests and debugging, and providing a complete production dossier.

We have particular expertise in PHY layer design and RF drivers, as well as testing, characterization, and pre-certification of protocols such as Sigfox™, LoRaWAN™, WMBUS, and other proprietary protocols.

We stand ready to apply our technical expertise to assist you in achieving successful project outcomes.

Trust our team to deliver solutions tailored to your specific needs. Contact us today to discuss your projects and discover how we can help you reach your technological goals.

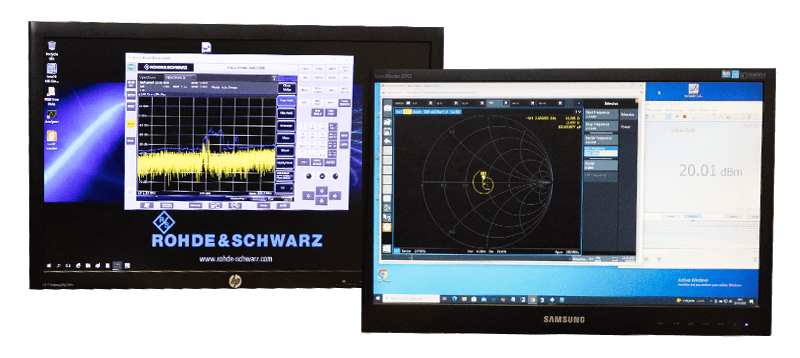

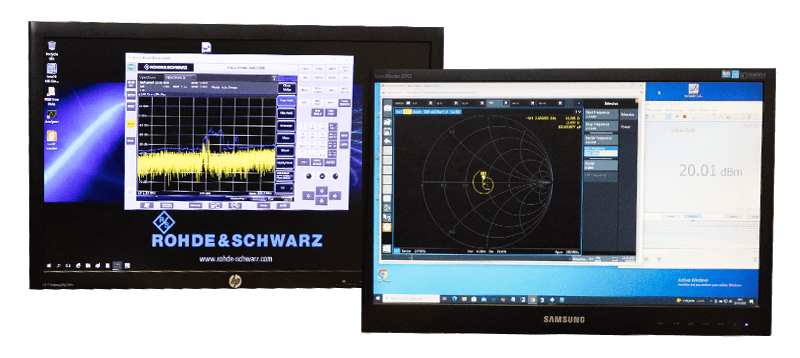

We offer comprehensive support for testing, characterization, and validation of your radiofrequency electronic products at every stage of development, from design to production and quality control.

Our testing capabilities cover both finished and semi-finished products, considering the operating temperature range, with static and dynamic modes of your product.

We focus on key aspects such as radiofrequency (radiated measurements, communication reliability, etc.), functional aspects (applicative functions, temperature reliability, embedded system, etc.), and energy aspects (consumption profiles, impact on energy solutions, etc.).

We tailor the duration and severity of tests based on the specific characteristics of your product, its use cases, and the different stages of design. Our goal is to provide comprehensive validation to ensure the quality and reliability of your products both individually and in the deployment configuration.

To conduct these tests, we have a wide range of measurement and characterization equipment, using proven methodologies in constrained areas such as Smart Metering.

This enables us to perform unit tests during development, as well as validation plans and ongoing quality monitoring throughout the product’s lifecycle.

We can also design dedicated software tools for specific tests.

By leveraging our expertise, you benefit from a comprehensive approach to testing, characterization, and validation of your radiofrequency electronic products.

We ensure that your products meet the highest quality standards and operate reliably and efficiently.

Contact us today to discover how we can help you ensure the quality and compliance of your radiofrequency electronic products.

At Hortus Technologies, we understand the importance of controlling development and production costs while meeting your required volumes and quality levels.

We adapt to your specific needs to ensure optimal efficiency.

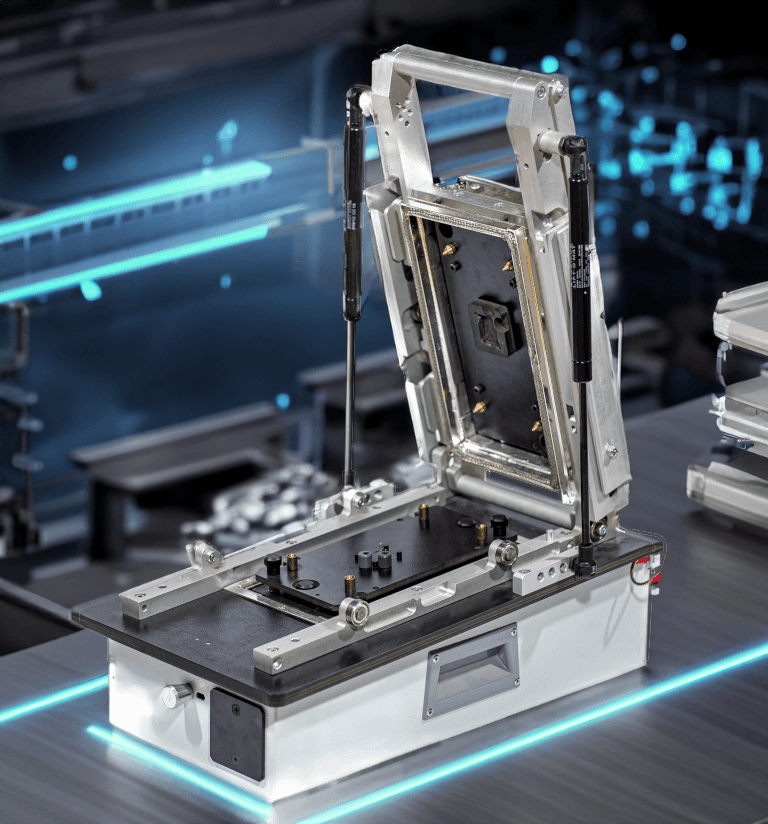

Hortus Technologies can assist you throughout the production setup process by designing test benches and software with a constant focus on cost optimization.

Whether for prototype development, mass production, or pre-series, we consider eco-design, integrating recycling practices and ensuring optimal lifespan for your products.

Our test benches are customizable, tailored to your envisaged production volumes. We accompany you from the initial idea to the prototype, from the prototype to the finished product, and from the pre-series to mass production.

At each stage of product definition, we assess Design for Manufacturability (DFM) and define the most relevant method in terms of investment costs, production time, and quality.

We also focus on product integration, mastering and anticipating potential risks such as performance losses, process repeatability, and costs.

We ensure that your manufacturing file is comprehensive, detailed, and compliant with requirements.

At Hortus, we are committed to providing you with efficient and cost-effective production solutions.

We pledge to work closely with you to ensure optimal integration of your products, reducing costs, and ensuring optimal quality.

Contact us today to discover how we can help you control the development and production costs of your products.”

ENSURE SUCCESSFUL MARKETING OF YOUR PRODUCTS

Vendargues

145 Rue de la Marbrerie Bât 3B, 34740 Vendargues, FRANCE