- EXPERTIZE

CHOICE OF SOLUTION

The definition of the solution is inherently linked to the choice of voltage management for the electronic board, considering the specificities of lithium primary batteries, whether associated with rechargeable reservoir supercapacitors or not.

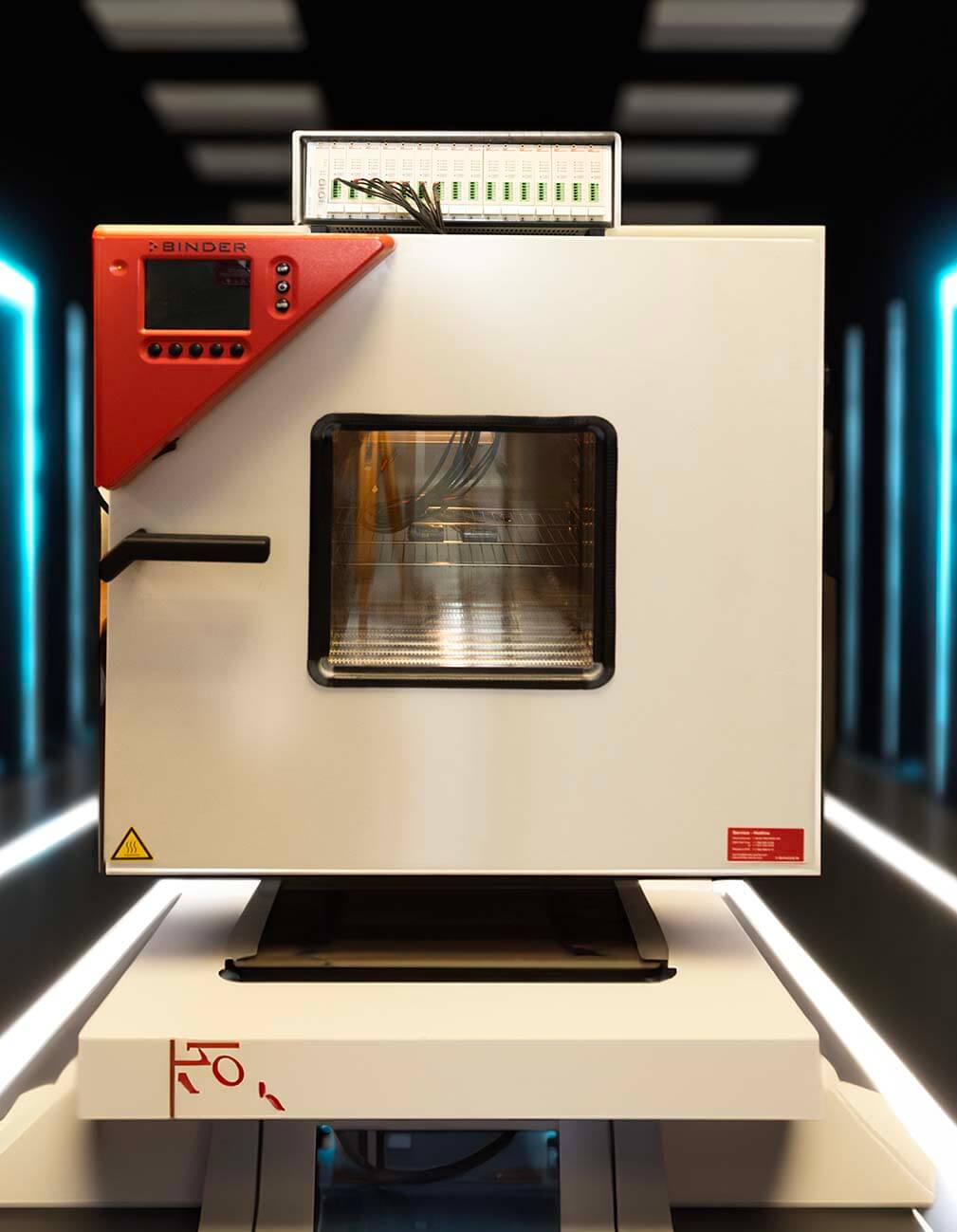

We have specialized test benches for energy solutions, allowing the emulation of consumption profiles. Thanks to our proven methodologies over the past 20 years, we can optimize the energy efficiency of your products and ensure an extended lifespan.

We have the ability to assist you in defining the best options, rigorously evaluating performance, and implementing energy optimization strategies.

Contact us today to discover how we can contribute to the success of your autonomous products in the market.